YFMA-850S Tsis Siv Neeg Vertical Multi function Laminating tshuab FOB NINGBO PORT USD

Main Specifications

| Qauv | YFMA-850S |

| Ceev | 10-110M / min (12000PCS / teev) |

| Max ntawv loj | W850 × L1050MM |

| Daim ntawv loj | W290 × L300 hli |

| daim ntawv hnyav | 80-500g / ㎡ |

| Pub ntawv pallet qhov siab | 1200 hli |

| Hwj chim | 20-25KW / teev |

| Tag Nrho Lub Zog | 60kw (380V AC3φ 50HZ) |

| L 8600 × W 1800 × H 2000 mm |

Cov haujlwm thiab tus cwj pwm

Tag nrho lub tshuab phab ntsa vaj huam sib luag txais cov machining chaw rau kev sib sib zog nqus ua kom ruaj khov khoom zoo, kev pab lub neej ntev thiab tsis muaj suab nrov.Cov khoom ua tiav ib zaug los ntawm CNC lathes thiab machining chaw los xyuas kom meej cov khoom tsim qauv, kev sib koom ua ke, thiab kev tswj hwm kev lees paub thiab kev cia khoom.

Lub tshuab no yog cov cuab yeej ntse ntsug lamination nrog qib siab ntawm automation, thiab muaj txiaj ntsig zoo thiab txuag hluav taws xob (kev siv hluav taws xob yog li 15 degrees ib teev).Lub tshuab muaj cov haujlwm ua tiav, txais kev tsim kho tib neeg, txais PLC kev tswj hwm hauv nruab nrab, thiab tuaj yeem kuaj pom qhov tsis raug Thiab cia li ua cov kev kho mob sib xws, lub tshuab ziab khaub ncaws siv lub tshuab cua kub, ua ke nrog kev ua haujlwm kom qhuav thiab cua sov, uas txhim kho lub drying efficiency ntawm acceleration thiab deceleration, thiab zoo heev txhim kho kev tswj kev ua tau zoo ntawm tag nrho cov tshuab.Nrog rau tib neeg-tshuab interface, kev ua haujlwm tau ntse dua thiab tib neeg.Nws muaj high-speed paper feeder, hmoov Remover, lamination thiab txheej ntaus ntawv, tiav cov khoom tawg thiab daim ntawv xa tshuab.

Lub ntsiab tsav ntawm tag nrho lub tshuab txais kev siv synchronous siv tsav, uas ua rau lub tsav ruaj khov thiab meej, thiab tib lub sijhawm ua kom qhov tseeb, thiab txhim kho kev ruaj ntseg thiab kev pabcuam lub neej ntawm lub tshuab zoo heev.(thawj coj los ntawm cov phooj ywg)

Lub tshuab tag nrho muaj lub ntsuas hluav taws xob ntsuas hluav taws xob los saib xyuas qhov voltage, tam sim no thiab lub zog ntawm lub sijhawm, thiab muaj lub zog siv hluav taws xob thiab tso tawm cov txheeb cais ntawm txhua qhov kev hloov.

Configuration Instructions

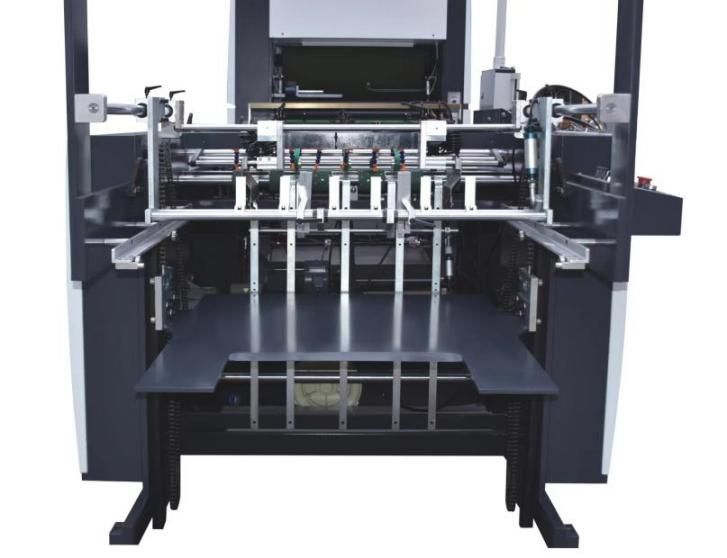

1. High-speed ntawv feeder

- Daim ntawv siab tshaj plaws: 1100mm;

- Nruab nrog longitudinal thiab lateral positioning mechanisms;

- Txais servo thev naus laus zis, PLC tswj thiab tib neeg-khoos phis tawj kev sib cuam tshuam hauv nruab nrab tswj;

- Txoj hauj lwm ntawm daim ntawv yog tswj tsis pub dhau ± 2 hli;

- Roj-dawb lub tshuab nqus tsev twj;

-Paper pawg nrhiav tau mechanism, ntawv tsis txaus nrhiav mechanism thiab lwm yam series ntawm sensing detection mechanisms.

2. Laminating party

-Lub tshuab tag nrho txais cov khoom siv high-precision synchronous siv thiab qee cov chains txawv teb rau kev sib kis;

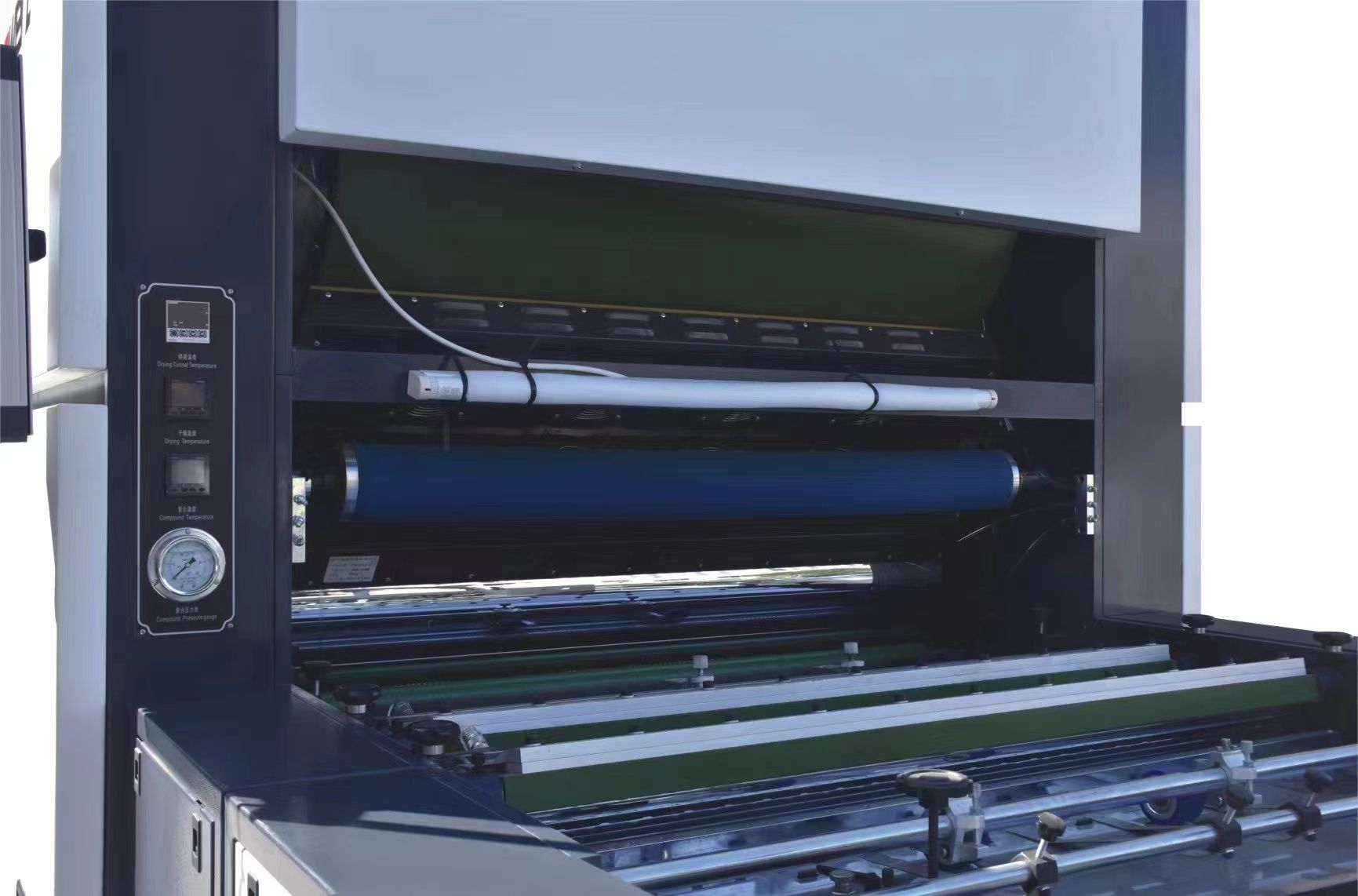

-380mm composite cua sov cov menyuam, txuam electromagnetic variable zog cua sov system;

-320mm imported silicone siab cov menyuam, nrog zoo kub thiab siab tsis kam thiab tsis-stick kev kawm;

-800mm ziab tshav kub rau cov menyuam, coated nrog cov khoom tsis-stick Teflon;

-Lub tshuab ziab khaub ncaws siv lub tshuab cua kub, ua ke nrog cov khoom siv ua kom qhuav thiab cua sov;

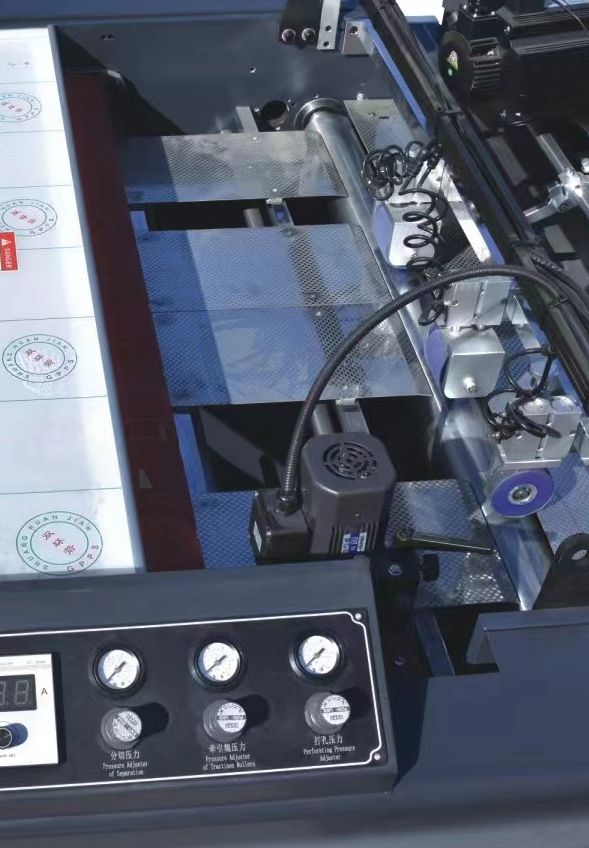

3. Slitting system

- Txais siv cov cuab yeej ua haujlwm tom qab txiav rau kev txiav;

- Los nrog ib tug disc cutout

- Siv lub hauv paus tswj hwm ntawm tag nrho lub tshuab kom ua tiav pneumatic tawg

4. Tsis siv neeg nqa tshuab

-Auxiliary suction thiab buffer system;

- Loaded nrog nthwv dej siab, sib tw nrog pneumatic tsis siv neeg ntawv flapping;

- Chaw thau khoom tsis siv neeg tsis lees paub ntaus ntawv;

- Sib phim daim ntawv jam nrhiav kom paub txog kev ntse ntse;

-(xaiv tau) Servo ntse board hloov yam tsis muaj kev saib xyuas phau ntawv.+

Cov npe hluav taws xob configuration

1.Low voltage Circuit Court breaker: Fabkis Schneider

2.2.Intermediate relay: Fabkis Schneider

3. Programmable maub los: Inovance Technology

4. Inverter: Inovance Technology

5. Rotary encoder: German SICK

6. Hloov fais fab mov: Taiwan Mingwei

7. AC contactor: Fabkis Schneider

8. Khawm: Fabkis Schneider

9. Kov npo: FLEXEM

10. Pneumatic Cheebtsam: AirTAC Taiwan

11. Photoelectric hloov: Japanese Panasonic

12. Lub cev muaj zog: Tuam Tshoj Dedong kis tau tus mob

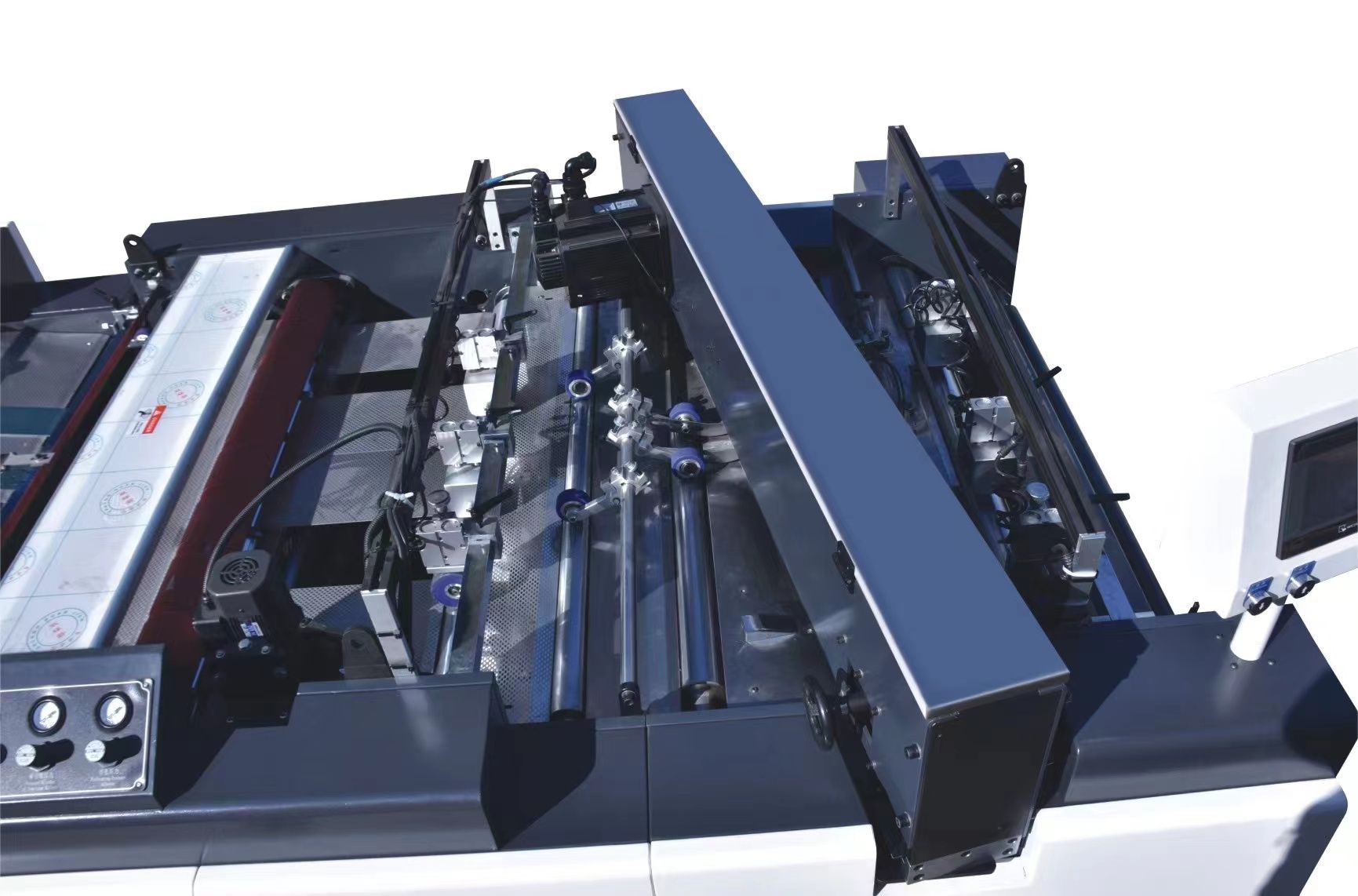

Configuration Center Duab

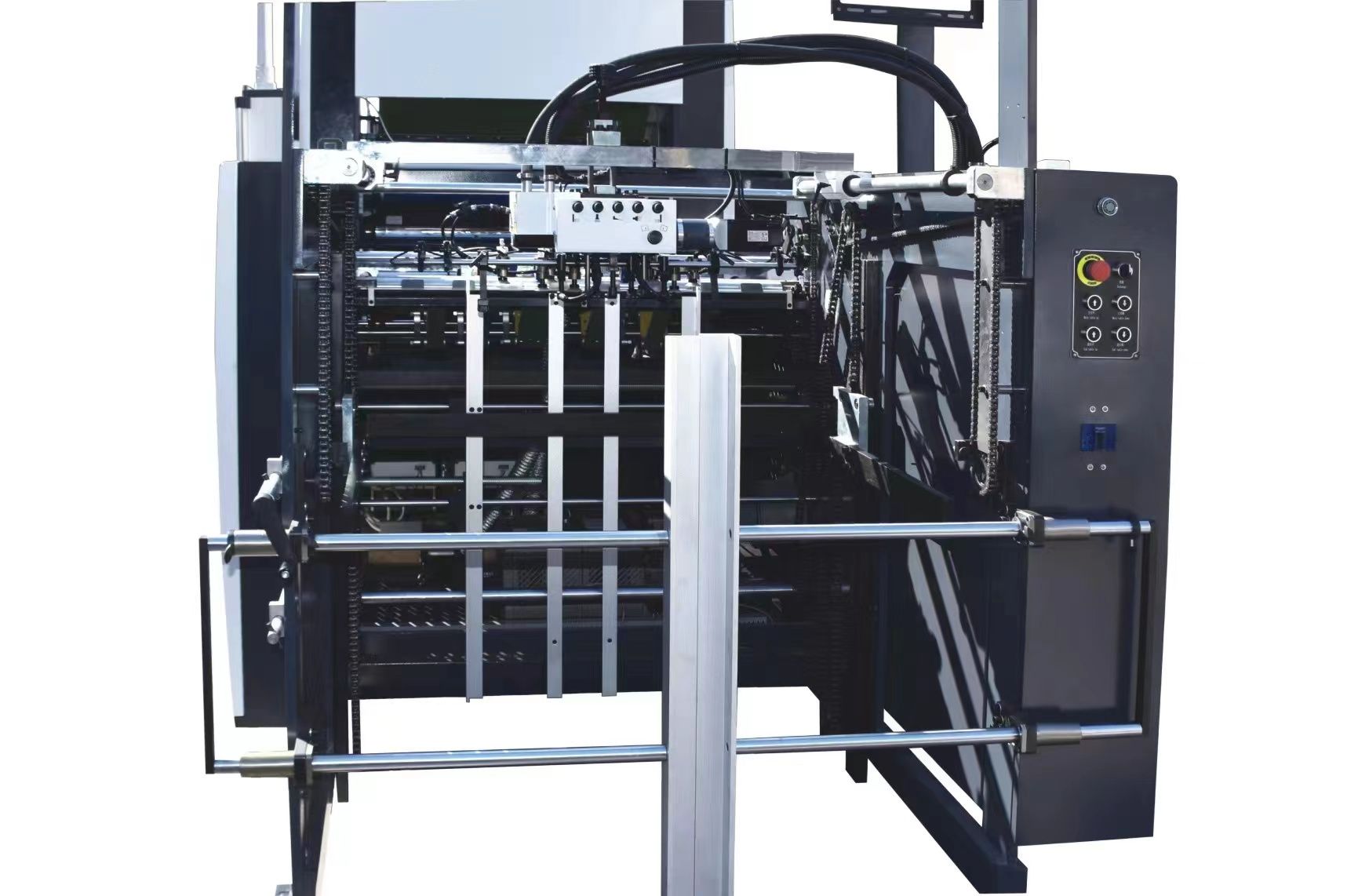

High Speed Automatic Paper Feeding System

High Precision Layers

Lub Hwj Chim Huv Huv

Electromagnetic cua sov system thiab infrared kub tswj qhov system

Lamination thiab txheej txheej mechanism

Disc ya riam mechanism

Slitting thiab wave pressure mechanism

Sau System

Feida kis tau tus mob

Chain Riam (Yeem)

Lwm Cov Cai

| (1) Lub sij hawm xa tuaj: 30-45 hnub tom qab tau txais koj cov nyiaj them ua ntej |

| (2) Chaw thau khoom & Chaw Nres Nkoj: Los ntawm NINGBO, Tuam Tshoj rau koj qhov chaw nres nkoj |

| (3) Cov nqe lus them nqi: 30% T / T tso nyiaj, 70% tshuav nyiaj li cas T / T them ua ntej khoom xa tuaj |

| (4) Lub sij hawm xa tuaj: 30 hnub |

| (5) Warranty: Ib xyoos dawb warranty. |